For detailed information, other images and documents, please select individual articles from the following table.

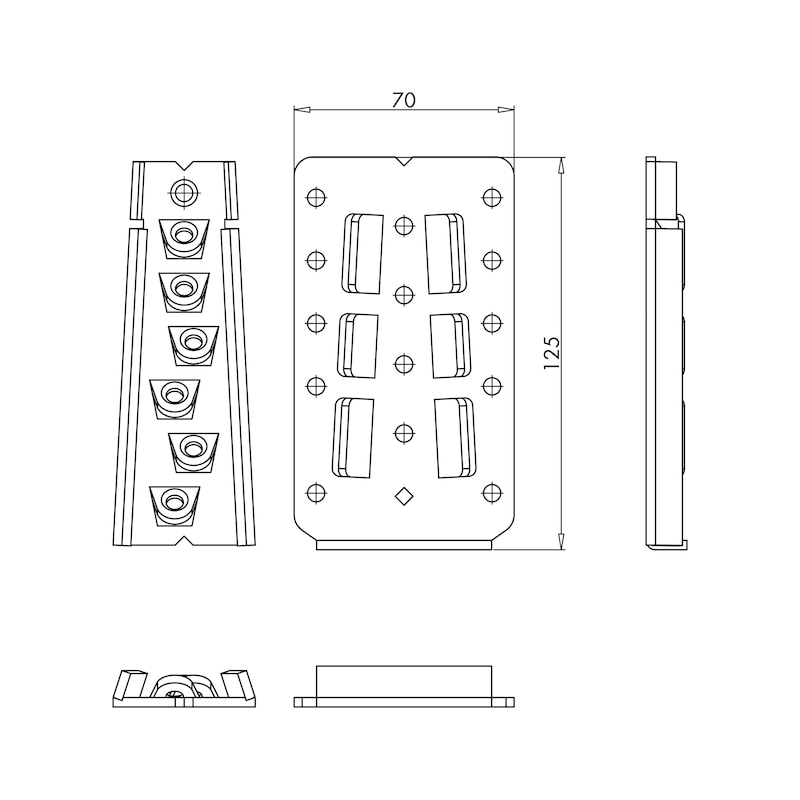

Concealed beam connector

This innovative concealed beam connector with high load-bearing capacity and low installation depth is ideal for concealed wood/wood connections (visible areas) of secondary beams to main beams or posts

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Sloping connections can be constructed at angles of 15° to 165° and gradients of 0° to 55°

- Screw into the end grain at an angle of 35° using ASSY 5 x 80 mm countersunk head screw with full thread

- The screw-in angle is determined by the sheet metal guide

- High load capacity coupled with low installation depth (14 mm)

- Conical, swallow tail-style geometry for self-centring and gap-free contact pressure

- High level of possible pre-fabrication in the workshop and easy and quick on-site installation

- Sheet metal batch hot-dip galvanised on both sides (S250GD + Z275 (approx. 20 µm)), thickness 3.0 mm, in accordance with EN 10346:2009

- Application in utilisation class 1 and 2 in accordance with EN 1995:2013

ETA-09/0301

It is advisable to use the corresponding milling template set for easy and quick pre-assembly.

Screw into grain-cut timber at an angle of 35°. The screw-in angle is determined by the shape of the tabs.

The transverse tension of the main beam must be verified separately. If necessary, the tension should be made using ASSY plus VG full-thread screws. For loads perpendicular to the secondary beam axis, the transverse tension must also be verified for the secondary beam. If the main beam is subject to torsion, it must be secured against twisting.

Select a template insert

Select a template insert

Attach template: The fixing holes are used to attach the template to the beam.

Attach template: The fixing holes are used to attach the template to the beam.

Set the trimming depth of 14 mm

Set the trimming depth of 14 mm

Mill the recess

Mill the recess

The upper thrust ring enables a simple and fast milling process without damaging the template.

The upper thrust ring enables a simple and fast milling process without damaging the template.

Mark center of secondary beam.

Mark center of secondary beam.

Place the swallow tail-shaped part of the connector centrally on the previously marked secondary beam and screw in the centring screw first of all. The connector must be mounted flush with the upper edge

Place the swallow tail-shaped part of the connector centrally on the previously marked secondary beam and screw in the centring screw first of all. The connector must be mounted flush with the upper edge

Then screw in the remaining screws at a 35° angle.

Then screw in the remaining screws at a 35° angle.

Fit the connector

Fit the connectorinto the prepared recess

in the main beam and

screw in the screws.

Hook the secondary beam into main beam from above

Hook the secondary beam into main beam from above

Simple mounting thanks tocentering aid.

Simple mounting thanks tocentering aid.

ETA-09/0301

Load-bearing connections of timber joists to timber main beams or posts in visible areas

Approved fasteners:

ASSY 4.0 countersunk head screw with full thread 5 x 80 to 120 mm (lg ≥ 72 mm) in line with ETA 11/0190 mm

Installation instructions:

- Select a template insert

- Place the swallow tail-shaped part of the connector centrally on the previously marked secondary beam and screw in the centring screw first of all. The connector must be mounted flush with the upper edge

- Screw in the remaining ASSY screws at an angle of 35°

- Fit the connector in the prepared recess of the main beam and screw in the screws

- Hook the secondary beam into the main beam from above

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!