For detailed information, other images and documents, please select individual articles from the following table.

ASSY® 4 PII CSMP universal screw Steel zinc-plated partial thread with underhead thread milling pocket head

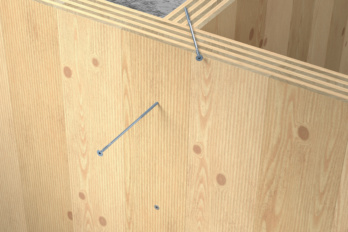

Special partial thread screw with underhead thread with tightening effect for flat, close-to-edge and high-load-bearing wood-wood and steel-wood connections with no gap in interior finishing or timber construction in dry indoor areas or damp areas

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

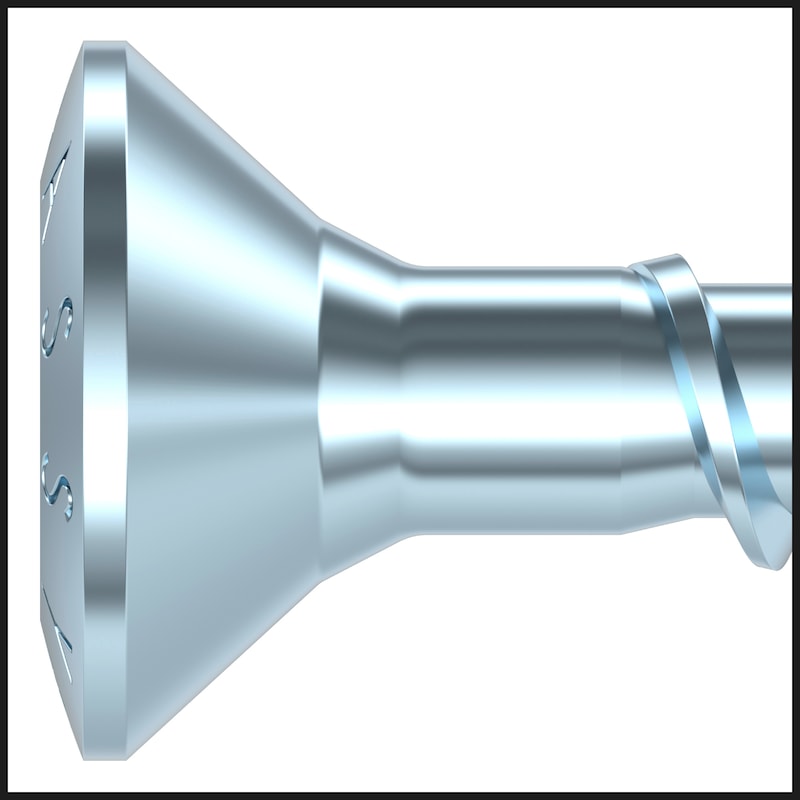

RW recess ensures optimal power transmission

- Larger contact surface at the bit offers increased power

- More stability, one-handed working and precise positioning due to the tight-fit recess and perfect fit of the bit

- Fewer bit changes, one bit for multiple screw diameters

- Compatibility with previous AW recess

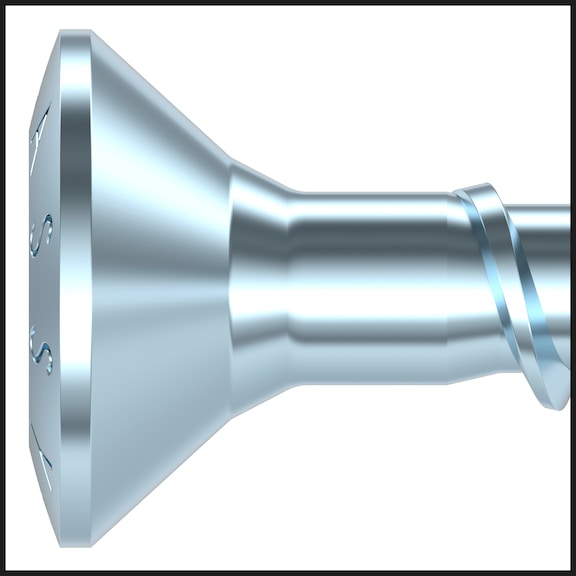

Innovative underhead thread

- Very high head pull-through (> ASSY 4 WH) due to supporting underhead thread and increased head diameter

- Gap-free assembly results from the pressure applied by the opposing grooved shank and the underhead thread with a smaller pitch, with a tightening effect of approx. 2 mm

- Suitable for timber-to-timber and steel-to-timber connections due to 90° countersunk head and identical external diameter of both threads

- Two wooden elements can be precisely joined thanks to the head fitting flush with the wood surface

Very easy to install

- Improved head countersinking and reduced risk of head breakage in hard wood surfaces (knotted areas) due to more uniform distribution of tension between head and underhead thread

- Simplifies assembly and reduces the range of screws that need to be kept on assembly vehicles by combining the characteristics of countersunk head screws and washer head screws

- Optimised piercing and engaging of the screw due to gentle thread start

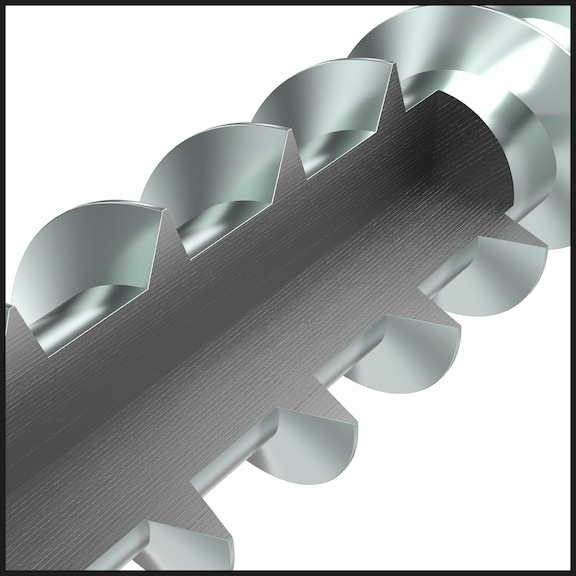

- Minimal splitting due to material displacement by the dome-shaped milling elements in the tip

Approved as per ETA-11/0190

- When fastening thin components, it is important to ensure that the screw head is flush with the wood surface.

- We recommend using the Würth software or corresponding design aids for planning and designing your installation. Dimensioning of ASSY screws can be carried out in the Würth timber construction software from a screw dia. of 5 mm

- ASSY 4, ASSYplus 4 and ASSYplus 4 VG chipboard screws are optimised for use in timber and engineered wood. For applications in plastic anchors where the working load can also be reduced, use only screws without an optimised thread tip (tip with milling ribs, drill tip, self-clearing groove etc.), such as the ASSY D screws with countersunk head or pan head

| Steel zinc-plated, utilisation class 1 and 2, draft 22/11/2023 |  | Characteristic load capacities of the connector | Fax,Rk | Fv,Rk |  |  |  |  | Dimensions | Art. no. | PU | ls | t1,min | t1,max,90/90 | t1,max,90/0 | 90°/90° | 90°/0° | 90°/90° | 90°/0° | Unit | mm | mm | mm | mm | kN | kN | kN | kN | ASSY 4 PII CSMP |

| Screwing and press gluing, thread length required lg =15xd | ||||||||||

| Key | General | |||||||||

| Component 1 (screw head) | Design value for load capacity | |||||||||

| Component 2 (screw tip) | ||||||||||

| Component thickness t2 ≥ls - t1 characteristic raw density ρk = 350 kg/m³ | ||||||||||

| 8x70/32 | 0190 440 807 | 50 | 70 | 32 | 38 | --- | 2,82 | --- | 2,50 | --- |

| 8x80/32 | 0190 440 808 | 50 | 80 | 32 | 48 | --- | 2,82 | --- | 2,75 | --- |

| 8x90/32 | 0190 440 809 | 50 | 90 | 32 | 58 | --- | 2,82 | --- | 2,75 | --- |

| 8x110/50 | 0190 440 811 | 50 | 110 | 32 | 60 | --- | 4,40 | --- | 3,15 | --- |

| 8x130/60 | 0190 440 813 | 50 | 130 | 32 | 70 | --- | 5,28 | --- | 3,37 | --- |

| 8x150/80 | 0190 440 815 | 50 | 150 | 32 | 70 | --- | 7,04 | --- | 3,81 | --- |

| 8x170/80 | 0190 440 817 | 50 | 170 | 32 | 90 | --- | 7,04 | --- | 3,81 | --- |

| 8x190/80 | 0190 440 819 | 50 | 190 | 42 | 110 | --- | 7,04 | --- | 3,81 | --- |

| 8x210/100 | 0190 440 821 | 50 | 210 | 42 | 110 | 50 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x230/100 | 0190 440 823 | 50 | 230 | 42 | 130 | 70 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x250/100 | 0190 440 825 | 50 | 250 | 42 | 150 | 90 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x270/100 | 0190 440 827 | 50 | 270 | 42 | 170 | 110 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x290/100 | 0190 440 829 | 50 | 290 | 42 | 190 | 130 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x310/100 | 0190 440 831 | 50 | 310 | 42 | 210 | 150 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x330/100 | 0190 440 833 | 50 | 330 | 42 | 230 | 170 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x350/100 | 0190 440 835 | 50 | 350 | 42 | 250 | 190 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x370/100 | 0190 440 837 | 50 | 370 | 42 | 270 | 210 | 7,87 | 2,64 | 4,31 | 2,55 |

| 8x210/120 | 0190 440 921 | 50 | 210 | 42 | 70 | 50 | 7,87 | 3,17 | 4,31 | 2,55 |

| 8x270/120 | 0190 440 927 | 50 | 270 | 42 | 150 | 110 | 7,87 | 3,17 | 4,31 | 2,55 |

| 8x330/120 | 0190 440 933 | 50 | 330 | 42 | 210 | 170 | 7,87 | 3,17 | 4,31 | 2,55 |

|

| |||||||||

| Component thickness t1,min ≤t1 ≤t1,max characteristic raw density ρk = 350 kg/m³ | Fax,Rd = kmod · Fax,Rk/ϒM Fv,Rd = kmod · Fv,Rk/ϒM | |||||||||

Approved as per ETA-11/0190

The requirements of the European Technical Approval (ETA) must be observed

For connecting two precisely fitting wooden elements without leaving a gap, in particular for structural timber constructions or load-bearing purposes.

Screws with a diameter of 8 mm and a thread length of 120 mm (15xD) are ideal for press-glue and screw joint.

The underhead thread has a reduced thread pitch and enlarged external diameter, allowing two wooden elements to be connected without leaving a gap.

For applications requiring a flat finish of the screw head on the wood surface.

For applications in utilisation class 1 and utilisation class 2 (from dia. > 4 mm)

- High-quality chromium(VI)-free blue passivated zinc surface protection, A3K layer thickness 8 µm

- Suitable for use in utilisation class 1 (indoor areas) and from dia. > 4 mm in utilisation class 2 (wet areas or covered outdoor areas) in accordance with EN 1995-1-1:2010-12 + DIN SPEC 1052-100:2013-08

- For screws from dia. 4.5 mm with zinc layer thickness 8 µm with Cr(III) passivation, the requirement of classification T2/C2 is fulfilled in accordance with prEN 14592:2017 (D)

- The maximum gap between the components to be joined must not exceed 2 mm

- ASSY screws are approved for quasi-static loads

- For optimal use of the screw, use the RW bit that fits exactly

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!