For detailed information, other images and documents, please select individual articles from the following table.

ASSY® 4 CSMP ZiNi BLACK timber screw Steel zinc-nickel-plated black partial thread countersunk milling pocket head

Universal partial-thread screw for fast, gap-free fastening of wood-to-wood connections (spruce).

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Ideal power transmission due to RW recess

- More power due to a larger contact surface at the bit

- More stability, one-handed working and precise positioning due to the tight-fit recess and perfect fit of the bit

- Fewer bit changes, one bit for many screw diameters

- Compatibility with previous AW recess

Significantly reduces the force required to screw in the screw

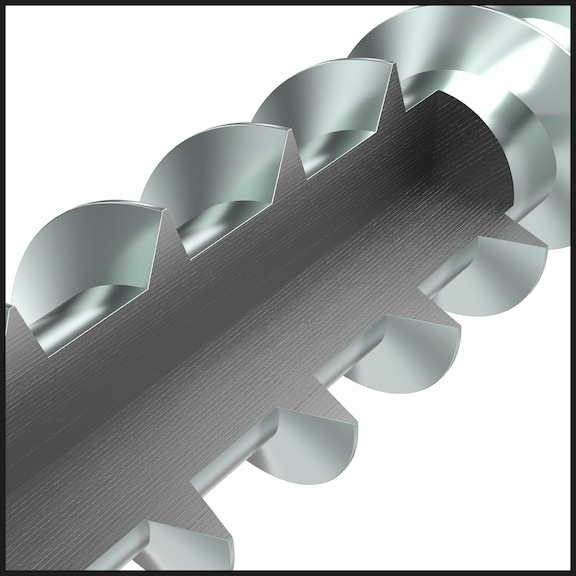

- Minimal splitting when the shank contacts the wood due to material displacement by the milling shank

- Minimised risk of screw breakage due to high breaking torque

- Reduced risk of injury from protruding metal chips due to the integration of the end mill into the thread

- Reduced wear and tear on application tools

No over-tightening with high feed performance

- Higher power transmission in hard woods due to reinforced, asymmetrical thread flank geometry of the coarse thread

- Better anchorage due to higher thread flanks

Smooth thread start ensures optimised piercing and biting of the screw

- Minimal splitting due to material displacement by the dome-shaped milling elements in the tip

- Minimal friction when screwing in the thread reduces the amount of force required

High strength values and ductility

- Tailored heat treatment guarantees high strength values and at the same time ensures high ductility

- We recommend using the Würth software or corresponding design aids for planning and designing your installation. Design of ASSY screws can be carried out in the Würth timber construction software from a screw dia. of 5 mm

- Due to mechanical force exerted by the bit during the screw-in process, corrosion resistance at the screw recess can be adversely affected.

- Do not use the screw in applications with direct exposure to the weather or in wet rooms with atmospheres containing chlorine gas. If used outdoors and in rooms that are constantly exposed to high humidity, please use ASSY 4 A2 or A4 stainless steel screws and, if the atmosphere contains chlorine, use HCR stainless steel screws

- ASSY 4, ASSYplus 4 and ASSYplus 4 VG chipboard screws are optimised for use in timber and engineered wood. For applications in plastic anchors where the working load can also be reduced, use only screws without an optimised thread tip (tip with milling ribs, drill tip, self-clearing groove etc.), such as the ASSY D screws with countersunk head or pan head

Approved as per ETA-11/0190

The requirements of the European Technical Approval (ETA) must be observed

For wood-to-wood connections designed to be joined tightly

The partial thread starting immediately below the shank allows for wood-to-wood connections designed to be joined tightly. In this case the thread is positioned entirely in the lower component.

For applications in utilisation class 1 and utilisation class 2 (from dia. > 4 mm)

- Five times higher corrosion protection of the zinc-nickel-plated surface, chromium(VI)-free 8 µm layer thickness, compared to zinc-plated yellow surfaces, 500 h according to the salt spray test in accordance with DIN EN ISO 9227

- For use in utilisation class 1 (indoor areas) and from dia. > 4 mm in utilisation class 2 (wet area or covered outdoor area) in accordance with EN 1995-1-1:2010-12 + DIN SPEC 1052-100:2013-08. The requirement of classification T2/C2 is fulfilled in accordance with prEN 14592:2017 (D)

- Not recommended for use in wood types rich in tannic acids or boiler-pressure impregnated woods in wet areas

- To increase the joining effect or head penetration resistance, we recommend using the product in conjunction with precisely fitting washers for ASSY 4

- ASSY screws are approved for quasi-static loads

- For optimal use of the screw, use the RW bit that fits exactly

- Partial-thread screws are ideal for connecting wooden components. To achieve optimum assembly of the components, the components to be fixed must not be thicker than the length of the shank

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!